Waterjet Pump Seals: High-Pressure Adaptation Solutions for Industrial Cutting

Waterjet Pump Seals: Core Barrier for High-Pressure Sealing of Waterjet Equipment

In the high-pressure operating system of waterjet equipment, Waterjet Pump Seals can be called the "safety lifeline" — once the seal fails, it will not only cause high-pressure water leakage and sudden pressure drop of the equipment, but also may trigger chain failures such as equipment shutdown and component corrosion, resulting in significant production losses. We specialize in the R&D of high-pressure sealing technology, and customize exclusive Waterjet Pump Seals solutions for major mainstream brand waterjet equipment such as KMT, BFT, and Resato. With extreme sealing performance and precise adaptability, we build a solid line of defense for the stable operation of equipment.

Submit your equipment model to get a free Waterjet Pump Seals adaptation list

Are you encountering these Waterjet Pump Seals problems under high-pressure operating conditions?

Waterjet equipment operates in high-pressure conditions of 20000-60000 psi for a long time, and ordinary seals are prone to aging, deformation, leakage and other issues. Improperly adapted Waterjet Pump Seals will further amplify these hidden dangers:

• Poor sealing leads to high-pressure water leakage, pressure fluctuation of the equipment exceeds ±5%, and significant deviations in cutting accuracy;

• Insufficient wear resistance of the seal, requiring replacement in as short as hundreds of hours, and frequent shutdowns for maintenance reduce production efficiency;

• Mismatch with the equipment pump body interface, loosening after installation, increasing the risk of seal failure;

• Insufficient temperature and medium resistance, rapid aging under harsh operating conditions, and a sharp decrease in the service life of Waterjet Pump Seals.

Choose our customized Waterjet Pump Seals to fundamentally solve the above pain points and make the high-pressure operation of equipment more secure.

Exclusive Waterjet Pump Seals for Three Major Brands: Customized Adaptation Solutions

1. Waterjet Pump Seals Exclusively Adapted for Resato Equipment

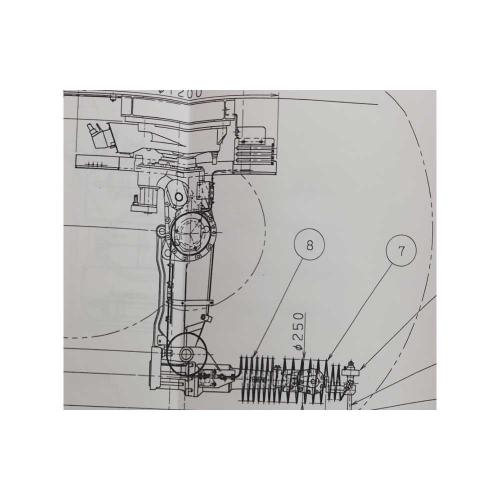

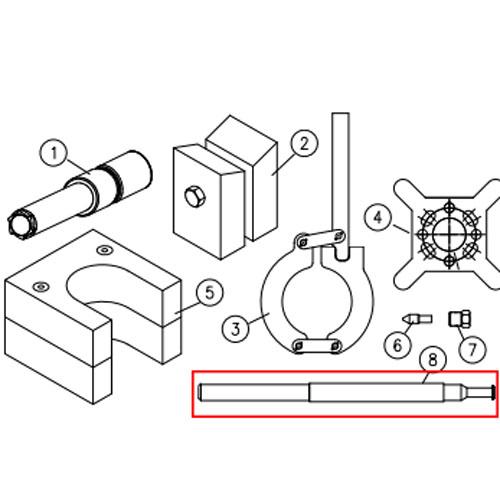

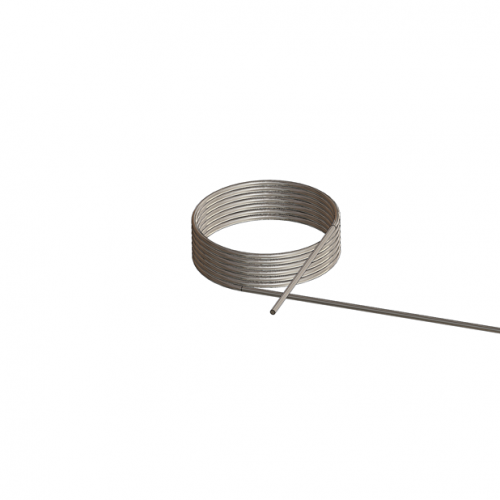

Customized for the characteristics of Resato R-Series and HydroPro series high-pressure water pumps, Waterjet Pump Seals adopt a composite sealing structure of "fluororubber + silicon carbide dynamic and static rings", specifically designed for ultra-high pressure operating conditions of 30000-60000 psi. Core technical parameters: The applicable medium is water-ethylene glycol mixture, working temperature ranges from -15℃ to 120℃, sealing pressure resistance ≥65000 psi, and leakage rate ≤0.1ml/h. Adaptation advantages: Precisely matches the shaft diameter specifications and installation groove size of Resato pump body, which can be perfectly embedded without processing or modification; The optimized wave spring preload structure can automatically compensate for the wear of the sealing surface, extending the service life of Waterjet Pump Seals to more than 2000 hours; Built-in impurity intrusion prevention lip, effectively resisting scratches on the sealing surface by particles in the water flow, adapting to the continuous operation needs of Resato equipment.

2. Waterjet Pump Seals Exclusively Adapted for BFT Equipment

Fitting the structural design of the water pumps of BFT Pro and Max series waterjet equipment, Waterjet Pump Seals select reinforced polytetrafluoroethylene (PTFE) material resistant to high pressure, paired with silicon nitride seal rings, which have excellent wear resistance and deformation resistance. Core technical parameters: Shaft diameter adaptation range is 30-80mm, sealing grade reaches IP68, working temperature ranges from -20℃ to 130℃, compatible with various working media such as pure water and emulsion. Adaptation advantages: Adopts split-type installation structure, solving the problem of narrow disassembly and assembly space of BFT equipment pump body, and a single person can complete the replacement of Waterjet Pump Seals within 15 minutes; The sealing surface undergoes mirror polishing treatment (roughness Ra≤0.02μm), reducing the friction coefficient and pump shaft wear; Aiming at the high-frequency start-stop operating conditions of BFT equipment, the seal compensation mechanism is optimized to avoid seal leakage at the moment of start-stop.

3. Waterjet Pump Seals Exclusively Adapted for KMT Equipment

Developed specifically for the water pumps of KMT SL-V and OmniJet series ultra-high pressure equipment, Waterjet Pump Seals adopt a composite process of "tungsten carbide reinforced matrix + perfluoroether rubber", which specifically enhances the sealing stability and impact resistance under ultra-high pressure operating conditions. Core technical parameters: Sealing pressure resistance ≥65000 psi, perfectly matching the ultra-high pressure output characteristics of KMT equipment; Working temperature ranges from -20℃ to 140℃, axial runout compensation ≤0.3mm, applicable media include high-pressure water, garnet suspension, emulsion and other common operating media of KMT equipment. Adaptation advantages: Precisely matches the high-pressure pump pressure feedback module of KMT equipment, compatible with the intelligent monitoring system of the equipment, and synchronizes the sealing status data of Waterjet Pump Seals in real time to early warn of leakage risks; The skeleton adopts a composite structure of 316L stainless steel + tungsten carbide coating, with high-pressure impact resistance up to 1200MPa, outstanding corrosion resistance and deformation resistance, adapting to the harsh operating conditions of KMT equipment for long-term continuous operation; The sealing lip adopts a stepped sealing design, fitting the high-speed rotation characteristics of KMT pump shaft, reducing friction loss and forming a double sealing barrier, greatly improving the sealing reliability under ultra-high pressure environment.

Core Technical Guarantee of Waterjet Pump Seals: Every Piece Undergoes Strict Verification

We deeply understand the importance of high-pressure sealing and have established a full-process quality control system to ensure that each set of Waterjet Pump Seals meets the requirements of high-pressure operating conditions:

• Material Selection: Core sealing materials have passed SGS certification, with fluororubber purity ≥99.5% and silicon carbide seal ring hardness ≥HRC62, ensuring wear resistance, high-pressure resistance and medium resistance;

• Simulated Operating Condition Testing: All Waterjet Pump Seals undergo 72-hour continuous operation testing on exclusive high-pressure simulation test benches, simulating the actual working pressure, temperature and medium environment of corresponding brand equipment to verify that the sealing performance does not decay;

• Precision Machining: Five-axis machining centers are used to process the sealing contact surface, with dimensional tolerance controlled within ±0.002mm to ensure precise fit with the pump body and pump shaft;

• Batch Traceability: Each set of Waterjet Pump Seals is equipped with a unique traceability code, allowing inquiry of material test reports and operating condition test data, with traceable and guaranteed quality.

Full-Cycle Service: Making Waterjet Pump Seals Selection and Use More Worry-Free

We not only provide high-quality Waterjet Pump Seals, but also create a full-cycle service closed loop to solve your worries:

1. Exclusive Selection Service: Professional technical team provides one-on-one customized Waterjet Pump Seals selection solutions based on the equipment brand, model and operating condition parameters you provide, avoiding adaptation errors;

2. Fast Delivery Guarantee: Core models of Waterjet Pump Seals for Resato, BFT, Flow, KMT and other mainstream brands are in stock, shipped within 48 hours after payment, and 24-hour expedited delivery is supported for emergency maintenance orders;

3. Technical Guidance Support: Provide detailed Waterjet Pump Seals installation videos and operation manuals, and engineers are available 7×12 hours online to answer questions about installation, commissioning and troubleshooting.

Lock in Your Exclusive Waterjet Pump Seals Adaptation Plan Now

No matter which brand of waterjet equipment you use, we can match you with precisely adapted and reliable Waterjet Pump Seals to protect the high-pressure operation safety of your equipment and reduce production losses.

Click [Contact Us Now] to submit equipment information, get free selection suggestions and accurate quotes, and receive one-on-one answers to Waterjet Pump Seals related questions.

We always adhere to the core of "precise adaptation, extreme sealing, and dedicated service", continuously optimize the technology and service of Waterjet Pump Seals, and help industrial cutting enterprises achieve stable production, cost reduction and efficiency improvement!