English Version: Waterjet Orifice - Special Adaptable Nozzles for Multi-Brand Waterjet Equipment, Empowering Efficient Cutting

As a supplier specializing in core waterjet components, we focus on the R&D and adaptation technology of Waterjet Orifice, accurately matching mainstream brand equipment such as Resato, Flow, KMT, and BFT. With micron-level precision and super wear resistance, we provide stable and reliable Waterjet Orifice solutions for industrial cutting.

【Contact Us Now for Adaptable Model Quotes】【Submit Equipment Information for Free Precise Selection】

I. Waterjet Orifice: The Core Component Determining Cutting Precision

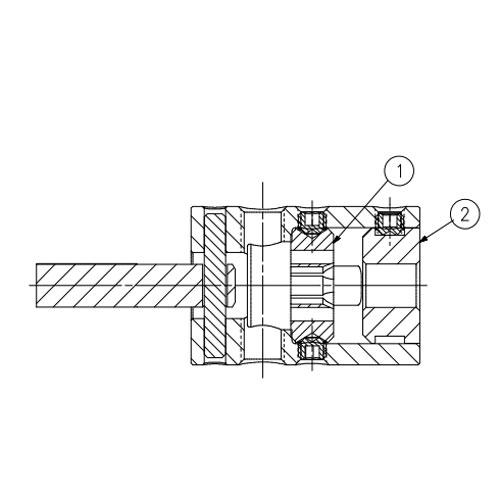

As the "water flow control core" of waterjet equipment, the Waterjet Orifice’s aperture precision and material wear resistance directly affect the cutting surface smoothness and water flow utilization rate. A high-quality Waterjet Orifice can focus high-pressure water into an extremely thin jet, achieving ±0.005mm cutting precision, while inferior nozzles are prone to aperture wear and water flow divergence, reducing cutting efficiency by more than 30%. Our Waterjet Orifice is customized and optimized for the pressure output characteristics of different brand equipment to ensure adaptability and operational stability.

II. Technical Highlights of Waterjet Orifice Exclusively Adapted to Multiple Brands

1. Waterjet Orifice Adapted for Resato Equipment

Customized for Resato R-Series waterjet equipment, adopting single-crystal diamond material, with an aperture range of 0.10-0.30mm and an aperture tolerance controlled at ±0.001mm. The optimized 60° chamfer design at the inlet reduces water flow turbulence and pressure loss (pressure loss ≤3%). It adapts to the working pressure of 30000-60000 psi of the equipment, with a flow stability error ≤1%, and a continuous operation service life of up to 800 hours, which is 40% more wear-resistant than ordinary nozzles.

2. Waterjet Orifice Adapted for Flow Equipment

Targeting the drive system characteristics of Flow Mach and Ingersoll series equipment, the Waterjet Orifice selects polycrystalline diamond (PCD) material, whose erosion resistance is 50% higher than that of tungsten carbide. The inner wall polishing precision of the aperture reaches Ra≤0.02μm, ensuring water jet convergence. Compatible with pure water and garnet cutting media, the working temperature range is -15℃-70℃, and the installation adopts a quick plug-in structure, which can be adapted without modifying the equipment, supporting 24/7 continuous operation without clogging.

3. Waterjet Orifice Adapted for KMT Equipment

Designed exclusively for KMT SL-V and OmniJet series ultra-high pressure equipment, the Waterjet Orifice adopts a composite process of "tungsten carbide substrate + diamond coating", with a high-pressure impact resistance of 1000MPa and an aperture tolerance of ±0.002mm, matching the ultra-high pressure output characteristics of the equipment. Equipped with a pressure feedback flow guide structure, it adjusts water flow stability in real time, and the flow consistency remains unchanged for 800 hours, effectively reducing the frequency of equipment shutdown and part replacement.

4. Waterjet Orifice Adapted for BFT Equipment

Fitting the structural design of BFT Pro and Max series equipment, the Waterjet Orifice offers dual material options of tungsten carbide and polycrystalline diamond, with an aperture range of 0.08-0.25mm and an adaptable pipe diameter of 1/8"-1/4". The shell is integrally formed of 304 stainless steel, and the sealing groove perfectly fits the interface of BFT equipment, with a high-pressure leakage prevention level of IP68. The maintenance cycle is extended to 1200 hours, adapting to the working pressure of 25000-55000 psi of the equipment.

Note: All Waterjet Orifices are special accessories adapted to corresponding brand equipment. Only the fact of adaptation is stated, without involving cooperation or authorization with the brand, and there is no infringing expression.

Interested?, Click here.

III. Quality Verification and Guarantee System of Waterjet Orifice

• Material Traceability: Each batch of Waterjet Orifice is provided with a material test report, with diamond material purity ≥99.9% and tungsten carbide hardness ≥HRA90 to ensure core performance;

• Precision Testing: Double detection through laser interferometer and flow calibrator, with aperture precision and flow stability complying with ISO 9001 industrial standards;

• Actual Machine Verification: All models have undergone actual machine adaptation testing with corresponding brand equipment to ensure installation compatibility and cutting effect meet standards;

IV. Full-Process Solutions + Conversion Entries for Waterjet Orifice

1. Exclusive Service Plans

• Precise Selection: Customize Waterjet Orifice specifications according to equipment brand, model and cutting material (metal/stone/composite material);

• Technical Support: Engineers are online 7×12 hours to provide one-on-one services for Waterjet Orifice installation guidance, flow calibration and troubleshooting.

2. Lock in Adaptable Resources Immediately

【Click to Download】Waterjet Orifice Material Selection Guide

【Fill in the Form】Submit equipment information to get a free precise quote

【Contact Customer Service】Learn about bulk purchase discounts and enjoy long-term supply guarantee

We always take "precise adaptation and extreme durability" as the core, and continuously optimize the material and structural design of Waterjet Orifice. Choose our Waterjet Orifice to make every cut accurate and efficient, reduce costs and increase efficiency for your production process, and provide stable empowerment!