Waterjet Nozzle - Precision-Adapted Core Cutting Component for Multi-Brand Waterjet Equipment

In a waterjet cutting system, the Waterjet Nozzle is a core component that determines cutting precision, efficiency, and stability. We focus on the R&D and adaptation optimization of high-quality Waterjet Nozzles, accurately matching mainstream brand waterjet equipment such as Flow, KMT, and Techni. With strict material standards and customized structural design, we provide reliable Waterjet Nozzle solutions for various industrial cutting scenarios (metal processing, stone cutting, composite material cutting, etc.).

I. Core Value of Waterjet Nozzle: Why Choose Precision-Adapted Professional Nozzles?

A high-quality Waterjet Nozzle can efficiently focus high-pressure water flow to achieve micron-level cutting precision; on the contrary, an improperly adapted or low-quality Waterjet Nozzle will lead to water flow divergence and excessive wear, which not only reduces cutting efficiency but also increases equipment loss and rework costs. Our Waterjet Nozzle solves industry pain points through three core advantages:

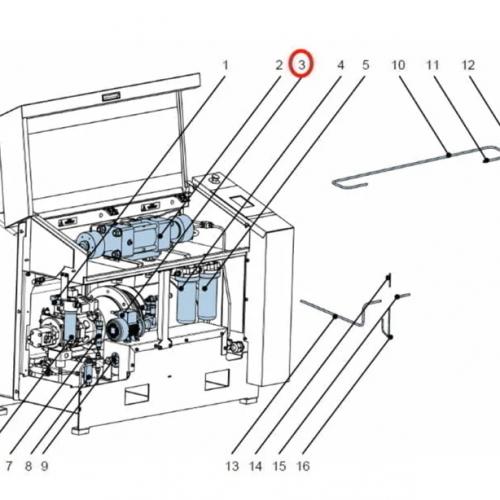

Customized Adaptation: According to the pressure output characteristics and interface specifications of different brand equipment, the Waterjet Nozzle structure is exclusively designed, which can be directly installed without modification;

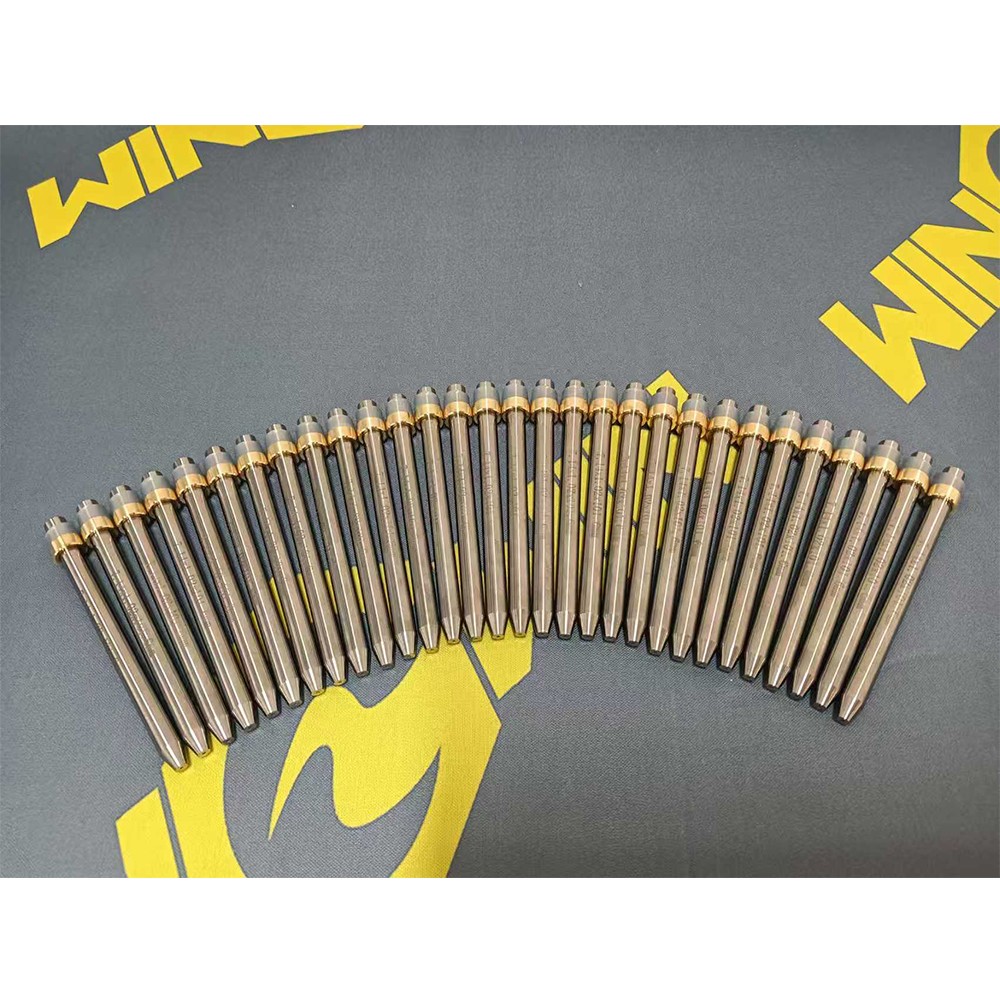

Extreme Wear Resistance: Core materials are high-purity wear-resistant materials such as polycrystalline diamond and tungsten carbide. After high-pressure erosion testing, the service life of the Waterjet Nozzle is increased by more than 50% compared with ordinary products;

Stability and High Efficiency: Optimized flow channel design reduces water flow resistance, and the flow stability error of the Waterjet Nozzle is ≤ 0.5%, ensuring consistent cutting precision during long-term continuous cutting.

II. Brand-Specific Customized Waterjet Nozzles: Technical Parameters and Adaptation Advantages

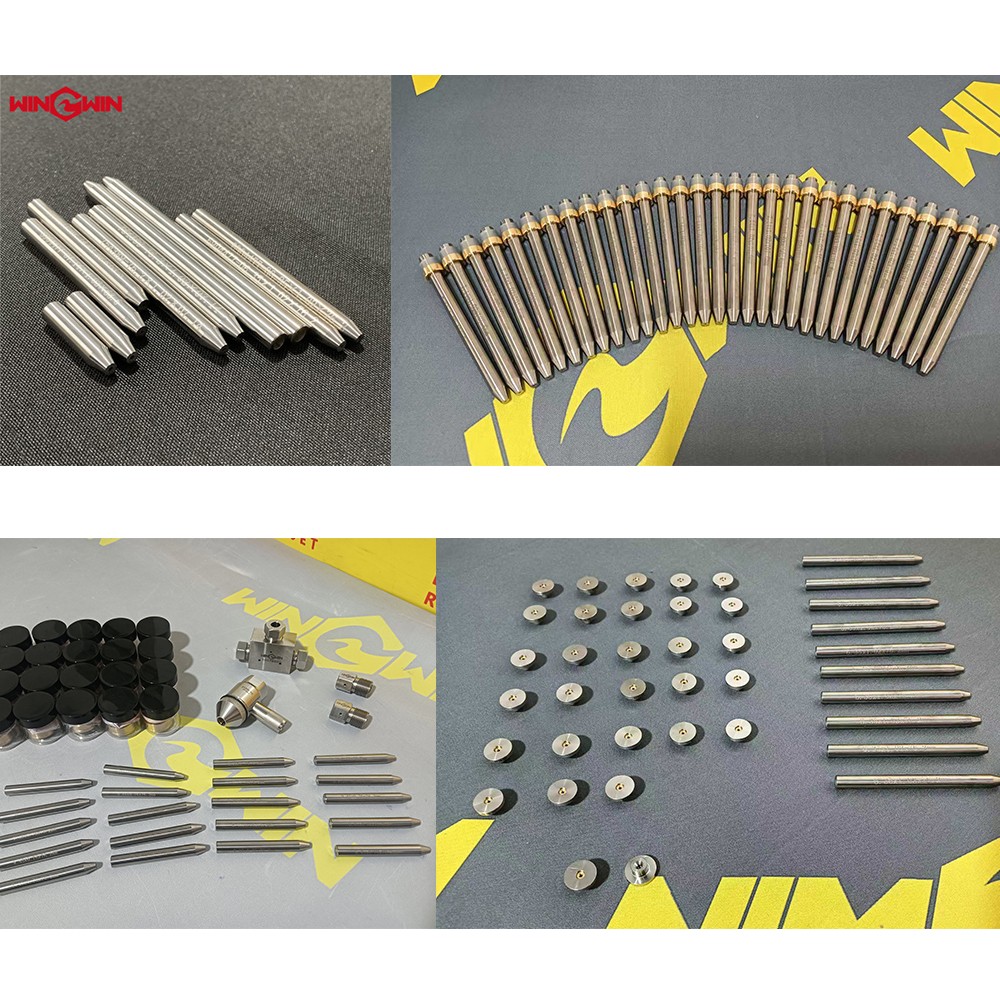

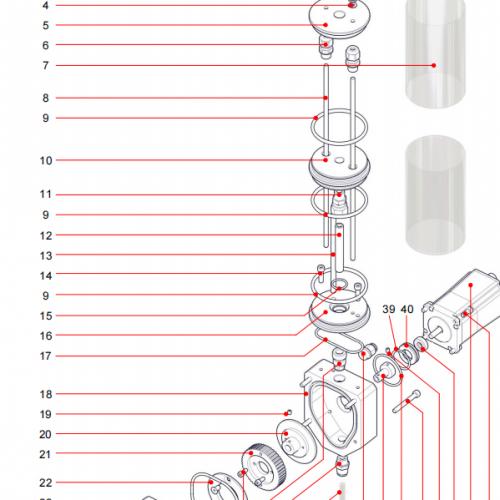

Exclusively developed for Flow Mach and Dynamic Waterjet series equipment, the Waterjet Nozzle adopts a combined structure of "polycrystalline diamond nozzle + zirconia ceramic guide sleeve", adapting to the ultra-high pressure working environment of 20000-60000 psi of the equipment. Core technical parameters: Aperture range 0.12-0.35mm, aperture tolerance ±0.001mm, optimized 55° inlet chamfer design, effectively reducing water flow turbulence and pressure loss (pressure loss ≤ 2%). Adaptation advantages: Perfectly matches the dynamic cutting system of Flow equipment, supporting 3D cutting. The Waterjet Nozzle installation adopts a quick-locking structure, reducing the disassembly and assembly time to within 3 minutes, greatly improving equipment operation and maintenance efficiency.

Developed for KMT SL-V and PowerMax series ultra-high pressure waterjet equipment, the Waterjet Nozzle adopts a composite process of tungsten carbide substrate + diamond coating, with high-pressure impact resistance of 1200MPa, adapting to the maximum working pressure of 60000 psi of the equipment. Core technical parameters: Flow range 0.5-3.0 L/min, repeat positioning accuracy ±0.005mm, working temperature -20℃-80℃, compatible with various cutting media such as pure water and garnet. Adaptation advantages: Built-in pressure-sensing flow guide structure, which can real-time adjust the water flow shape of the Waterjet Nozzle, adapting to the intelligent pressure control system of KMT equipment. When cutting hard materials (such as titanium alloy and granite), the efficiency is increased by 30%, and the cutting surface is burr-free.

Fitting the structural characteristics of Techni Waterjet Pro and G2 series equipment, the Waterjet Nozzle offers dual material options of tungsten carbide and polycrystalline diamond, with an aperture range of 0.08-0.28mm and an adapted pipe diameter of 1/8"-3/8". Core technical parameters: Sealing grade IP68, excellent high-pressure leakage prevention performance, maintenance cycle up to 1500 hours, adapting to the working pressure of 25000-55000 psi of the equipment. Adaptation advantages: The Waterjet Nozzle shell is integrally formed of aviation-grade aluminum alloy, which is 15% lighter than original accessories, reducing equipment movement load. At the same time, it reserves a sensor installation interface to support the intelligent monitoring function upgrade of Techni equipment.

Note: The above Waterjet Nozzles are all general accessories adapted to corresponding brand equipment. Only the fact of adaptation is stated, and there is no cooperation or authorization relationship with the brand. The product design and production comply with general industry standards, without any infringing expressions.

III. Waterjet Nozzle Quality Verification System: Every Piece Stands the Test

We implement full-process quality control for each batch of Waterjet Nozzles to ensure the stability and reliability of the products delivered to customers:

Material Testing: The purity of the core material of the Waterjet Nozzle is tested by a spectrum analyzer, with diamond material purity ≥ 99.9% and tungsten carbide hardness ≥ HRA92 to ensure wear resistance;

Precision Calibration: A laser interferometer is used to accurately calibrate the aperture and concentricity of the Waterjet Nozzle, with errors controlled at the micron level, complying with ISO 9001 quality standards;

Actual Machine Testing: All models of Waterjet Nozzles undergo continuous cutting tests for no less than 200 hours on corresponding brand equipment to verify adaptability, stability, and cutting effect;

IV. Exclusive Services: Making Waterjet Nozzle Selection and Use More Worry-Free

1. Full-Process Technical Support

A professional engineer team is online 7×12 hours to provide you with one-on-one services such as Waterjet Nozzle selection guidance, installation and commissioning tutorials, and troubleshooting, solving various problems during use. Whether you are replacing old Waterjet Nozzles or need to adapt to new specifications of nozzles for equipment upgrades, we can respond quickly to your needs.

2. Flexible Delivery Plan

Core models of Waterjet Nozzles are in stock and will be shipped within three working days after payment; emergency orders support 24-hour expedited production and shipping to ensure that your production schedule is not affected.

Get Your Exclusive Waterjet Nozzle Adaptation Plan Now

Whether you use Flow, KMT, or Techni brand waterjet equipment, we can match you with a precision-adapted and high-quality Waterjet Nozzle. Click the button below to submit your equipment model and cutting needs to get free selection suggestions and accurate quotes!

We always adhere to the concept of "precision adaptation, quality first, and dedicated service", continuously optimize the design and production process of Waterjet Nozzles, and help industrial cutting enterprises reduce costs, increase efficiency, and enhance competitiveness. Choose our Waterjet Nozzle to make every cut more precise, efficient, and stable!