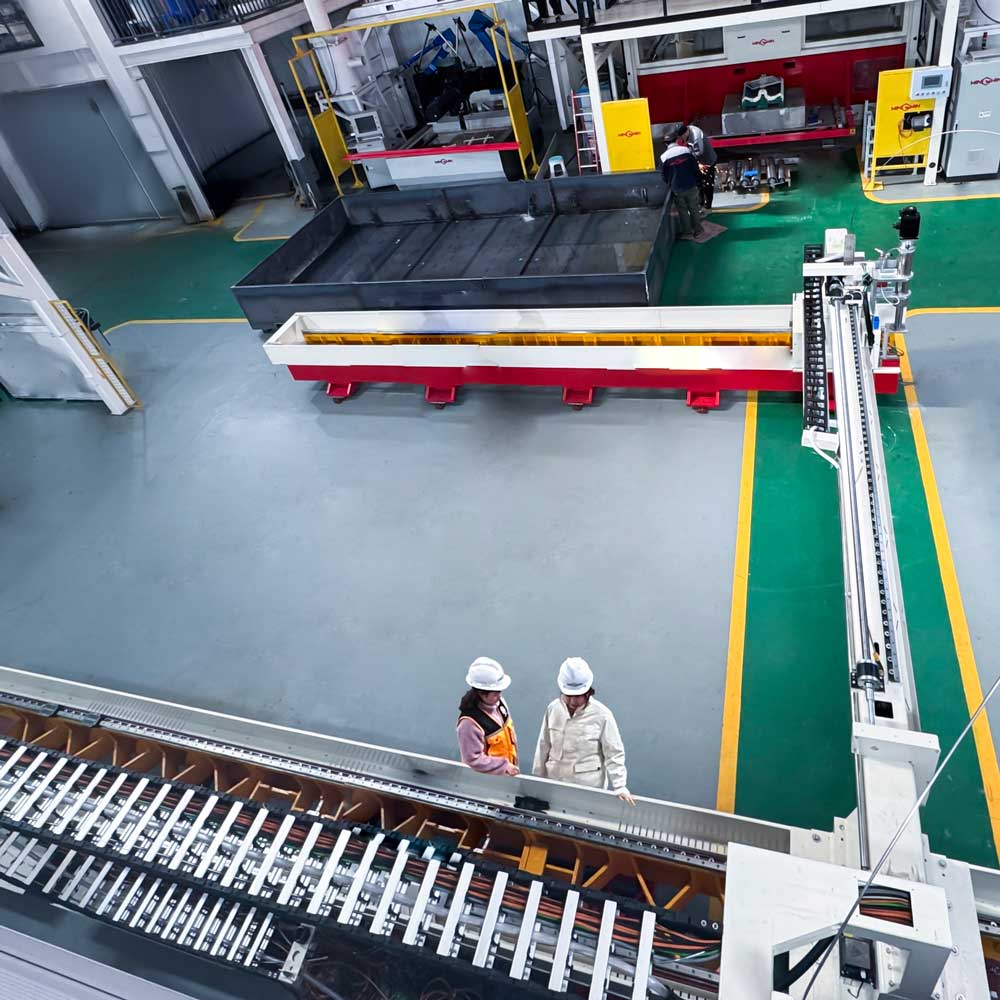

6 meters by 3 meters large size waterjet cutting machine sold to America

6 meters by 3 meters large size waterjet cutting machine sold to America

WATERJET SPARE factory sold waterjet cutting machine to the United States.

A 6-meter long and 3-meter wide waterjet cutting machine (the workbench size is typically approximately 6x3 meters, or a 6x3-meter sheet) is irreplaceable in many industries that demand large-format, high-precision, and heat-free cutting due to its vast processing range and unique advantages of cold cutting. It is primarily used in the following industries:

1. Architectural Decoration and Stone Processing

Large Stone Mosaic and Curtain Walls: Used for cutting large-format slabs of marble, granite, and artificial stone to create complex patterns, staircases, countertops, and building facades.

Artistic Sculpture: Suitable for creating large-scale stone sculptures, relief murals, and other artworks with high precision and no cracking.

2. Aerospace and Defense Industry

Composite Material Components: Cuts carbon fiber and glass fiber reinforced composite (CFRP/GFRP) fuselage components, wing skins, etc., avoiding delamination or thermal damage.

Specialty Metals: Processes aerospace materials such as titanium alloys and aluminum alloys for prototype production or component manufacturing.

Bulletproof Materials: Cuts bulletproof materials such as aramid and UHMWPE, with clean edges that do not affect material properties.

3. Rail Transit and Automobile Manufacturing

Interior Parts and Body: Cutting train interior panels, flooring, automotive interior composite materials, carpets, sound insulation materials, etc.

Prototype Development: Rapid prototyping for new car models and concept car components.

Special Vehicles: Cutting large body panels or functional components for fire trucks, RVs, etc.

4. Shipbuilding and Marine Engineering

Ship Hull Insulation Materials: Precision cutting of large fireproof, soundproof, and thermal insulation panels.

Interior and Furniture: Processing interior trim panels and furniture for ship cabins.

Composite Material Hulls: Repairing or cutting fiberglass (FRP) hull components.

5. Energy and Environmental Protection Equipment

Wind Power Equipment: Cutting large composite materials for wind turbine blades (for repair or molding) and insulating gaskets.

Environmental Protection Equipment: Processing large sheet metal components for wastewater treatment and waste gas treatment equipment.

6. Heavy Industry and Machinery Equipment Manufacturing

Large Machinery Exterior Covers and Protective Plates: Cutting steel and stainless steel plates to create equipment shells and safety guards.

Conveying Equipment: Manufacturing conveyor belt baffles, hoppers, etc.

Mold Industry: Trimming and cutting foam molds and composite material molds.

7. Advertising Signage and Exhibition Display

Large Signage: Cutting acrylic, PVC foam board, aluminum composite panel, etc., to create outdoor billboards and 3D lettering.

Exhibition Stands and Props: Rapidly processing large back panels and irregularly shaped structural components for exhibitions.

8. Furniture and Interior Design

Customized Furniture: Cutting large-format solid wood (composite) panels and artificial stone countertops to achieve complex designs.

Artistic Partitions and Decoration: Processing decorative partitions or wall art installations made of metal, glass, and wood.

9. Research and Education

Universities and Research Institutes: Used for experimental sample preparation in materials science, engineering mechanics, and other fields, especially suitable for research on heat-sensitive new materials.

Advantages Summary:

* **Large Format Efficiency:** The 6x3 meter worktable allows for the simultaneous processing of entire standard sheets of board (e.g., common board sizes of 2440x1220mm) without splicing or moving materials, significantly improving efficiency and reducing seam errors.

* **Cold Cutting Characteristics:** No heat-affected zone (HAZ), preserving the material's inherent properties, and producing no toxic gas emissions, making it environmentally friendly and safe.

* **Material Versatility:** Capable of cutting virtually any material (metal, stone, glass, ceramics, plastics, rubber, composite materials, etc.).

* **High Precision and Flexibility:** Combined with five-axis technology, it enables three-dimensional bevel cutting, meeting complex and irregular shape processing needs.

Examples of typical processed parts: Large composite material trimming for wind turbine blade molds

Large stone map or company logo reliefs

Anti-slip plate cutting for yacht decks

Forming of aircraft cabin interior panels

Stone processing for giant island countertops in integrated kitchens

These large-scale waterjet cutting machines are typically high-value production tools invested in by companies to meet specific needs for processing large-format, batch, or large single-item products. They significantly enhance a company's core competitiveness when undertaking large-scale, high-precision projects.

If you require this 05069703 Pneumatic Control Valve HP Normally Open Dump Valve to our customer,click here